Developed together with the main OEM’s the ITB compacting felts are designed for tubular or open-width knitted fabrics.

Made with meta-aramid fibres, e.g. Nomex®, they have a very flexible and smooth non-marking surface which ensures maximum shrinkage and dimensional stability of processed fabric and a long working life.

One only premium felt style with thickness range from 12mm to 22mm is suitable for all brands of compacting calenders.

The ITB sanfor felts are made of special technical grade fibres having high tensile strength for use in the production of woven fabrics such as denim, bed sheeting, shirting, terry and other types. They are heat-set and pre-stressed for dimensional stability, are finely textured on both sides and guarantee excellent air permeability.

Special fibres may be used or chemical treatments applied for demanding applications.

Specifically designed for continuous decatizing and setting machines, they have a seamless construction to leave no imprints and are fleece-layered to give fabric a softer, fuller hand.

In addition the ITB decatizing felts and shrink on sleeves offer excellent stability and tracking properties.

Special style with heat and chemical resistant synthetic fibres available for the most modern machines with pressurized steam.

These felts are made with meta-aramid fibres, e.g. Nomex®, to withstand even the highest temperatures. They are heat-set for minimal widthwise shrinkage and provide a precise and uniformed transfer of colours to the processed fabric with the sharpest definition.

The ITB transfer printing felts, available in widths up to 5000mm, are the choice of the world’s foremost machine manufacturers.

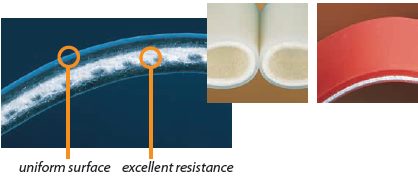

Endless needled felt belts coated with silicone and smoothly ground for use on high-performance continuous pressing/setting machines for woollen and wool blended fabrics.

These belts, coated with special chemical-resistant silicones to the exact specifications of machine manufacturers with an unrivalled level of surface finish and durability, withstand pressures exceeding 10kg/cm2.

ITB silicone coated belts also equip special calenders used to laminate different fabric layers.